◆ What is HPM?

| Conventional PM | MIM | HPM (All New) | |

|---|---|---|---|

| Cost | Low | High | Medium |

| Part Shape | 2D | 3D | 2D |

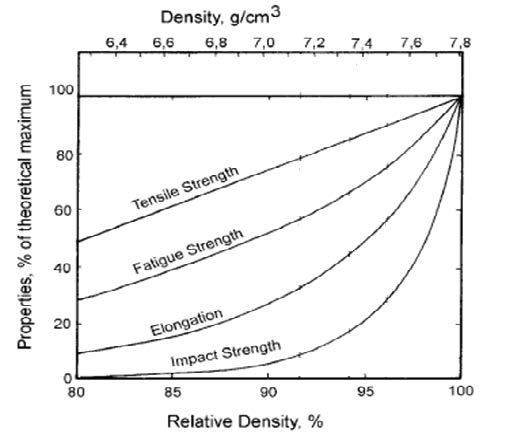

| Sintered Density | Low | High | High(same as MIM) |

| Mechanical Properties | Fair | Good | Good (same as MIM) |

| Cosmetic Finish |  |

|

|

- PM

Powder size 50~100 um

- MIM

Powder size below 15 um

- HPM

Powder size below 15 um

- Pre-treatment

Powder size 50~100 um

- Sintering Temperature

1120-1250°C

1300~1400°C