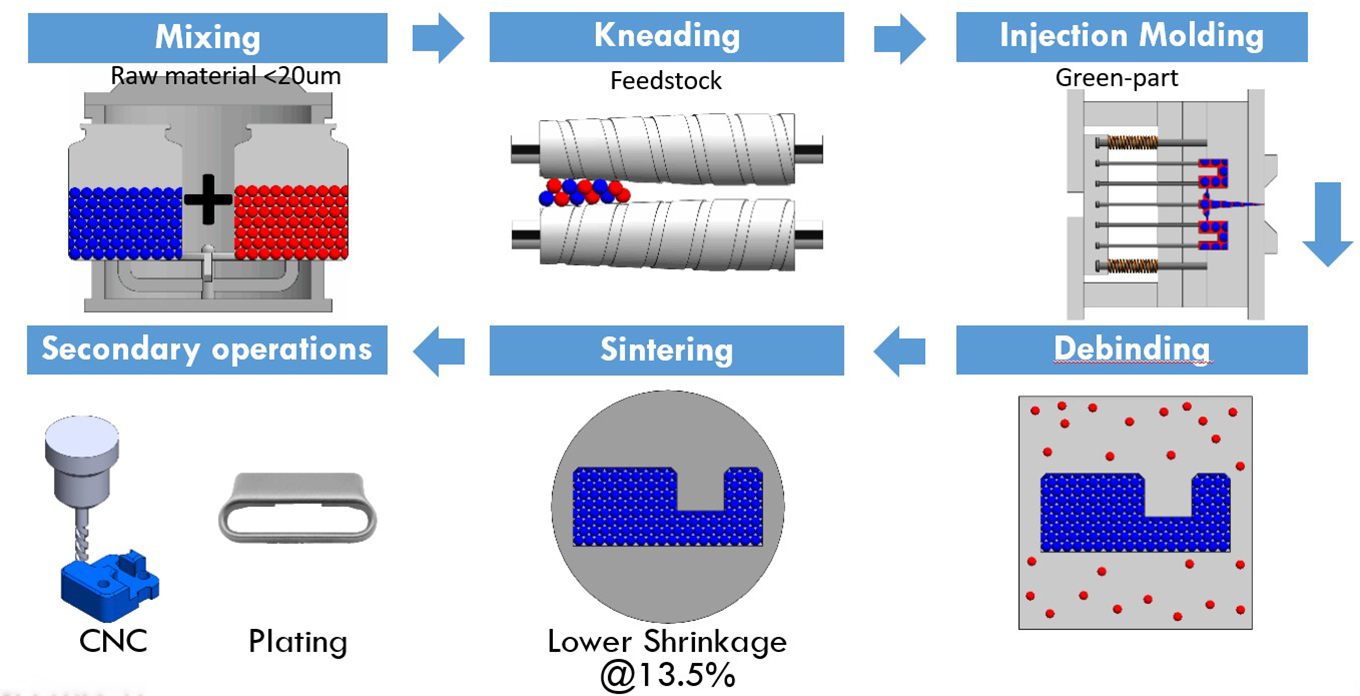

◆Process flow of MIM

◆Mechanical Property of Materials we provide

| Metal Types | Density (g/cm3) | Tensile Strength (MPa) | Elongation (%) | Hardness | Magnetic Response |

| 316L | >7.5 | 500 | 40 | HRB 50 ~ 60 | N/A |

| 17-4PH (As-Sintered) | 7.5 | 900 | 6 | HRC 23 ~ 26 | Low |

| 17-4PH (Heat-Treated) | 7.5 | 1190 | 5 | HRC 33 ~ 40 | Low |

| F75 | >7.5 | 728 | 23 | HRC 29 ~ 36 | N/A |

| 4605 (As-Sintered) | 7.5 | 440 | 15 | HRB 70 ~ 80 | Average |

| 4605 (Heat-Treated) | 7.5 | 1655 | 2 | HRC 48 ~ 52 | Average |

| 4605 Modified | 7.5 | 1800 | 5 | HRC 48 ~ 53 | Average |

| 1010 | 7.6 | 300 | 12 | HRB 40 | Good |

| SKD-11 (D2) (Heat-Treated) | 7.7 | 800 | < 1 | HRC 55 ~ 62 | Average |

| 420 | 7.2 | 1200 | 1~2 | HRC 46 ~ 50 | Average |

| 440C | 7.6 | 800 | < 1 | HRC 50 ~ 57 | Average |

| W-Ni-Cu | 17.8 | 780 | 3 | HRC 28 ~ 32 | Average |

| W-Ni-Fe | 18 | 950 | 8~9 | HRC 28 ~ 32 | Average |

| Kovar | >8.10 | Thermal Expansion Coefficient (CTE): 5.5x10-6 m/m/K | Average | ||

| Cu | 8.5 | 160 | 30 | - | - |